Take you to understand the material structure of the best-selling UVC lamp beads

发布时间:2022-04-02 15:54

来源:萤光创新

The most popular product in the LED industry this year is the UV disinfection products of UVC series. The last article explained in detail what UVC is and the principle of UV disinfection and sterilization. In this issue, we will take you to understand the materials we use for the mass production of UVC light source.

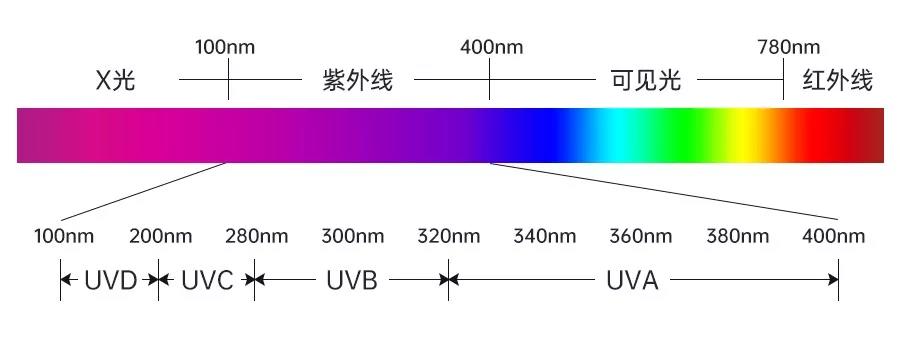

Let's review the relevant knowledge of UVC ultraviolet light first:

Ultraviolet (UV) has higher photon energy than visible light. High-energy photons may degrade some materials and produce physical or chemical changes (that is, articles will soon age and decompose after being exposed to the sun for a long time).

UVC, a subclass of ultraviolet radiation with a wavelength of 200 to 280 nm, does not exist in the sunlight on the ground. Because light with a wavelength lower than 300 nm will be absorbed by the ozone layer in the atmosphere, there has been little public research data on UVC degradation materials.

As the sterilization and disinfection effect of UVC is widely recognized, more and more products will design and use UVC as the disinfection scheme. At this time, we need to understand the material degradation principle including high-energy ultraviolet UVC light, and take the influence of UV degradation into account in the material design of products, so as to prolong the service life of products.

The principle of UV degradation of three types of materials:

1. Metal

Metal is characterized by metal bonding, which is composed of closely packed atoms arranged in a periodic lattice structure, and all atoms share a delocalized electron "cloud". Because metals have highly movable electrons, they are good conductors of electricity and heat and are prone to interfere with electromagnetic radiation, such as light and radio waves. This explains why metals are opaque and reflect a certain degree of light. This is because free electrons can be used to absorb photon energy without energy transition or bond dissociation, so metals are almost completely unaffected by ultraviolet rays.

2. Ceramics

Ceramic materials are formed by ion bonding, and the lattice with periodic structure contains positively and negatively charged ions. Most ceramics are metal oxides, and a few ceramics are nitrides, borides and carbides with strong covalent bonds. In contrast to metals, ceramic ions have tightly bound electrons, so they have high bonding strength, can withstand extreme temperatures, usually have extremely high chemical inertia and are good electrical insulators. This high bonding strength and chemical inertia make the ceramics completely unaffected by ultraviolet radiation.

3. Quartz

Amorphous silica (SiO2) in quartz material is a kind of material showing ionic bonding and covalent bonding. It can pass through UVC, which is very important for the ultraviolet industry. The main mechanism of ultraviolet absorption in quartz is related to impurities and defects. Impurities such as iron and other metals, the electrons of these metal atoms can be raised to a higher energy level or released from atoms, so they can be used to interfere with electromagnetic radiation, form the so-called "color core", and reduce the ultraviolet transparency of glass over time. There are also inherent atomic defects in quartz, such as unbound silicon and oxygen atoms, which will absorb certain vacuum ultraviolet (VUV) and UVC.

4. Polymer

Polymers contain a variety of materials, which are characterized by long molecular chains, entanglement and interconnection of molecular chains. They themselves exhibit covalent bonds, usually containing carbon components. Covalent bond is the sharing of electrons between two or more atoms, so that the constituent atoms can fill their outermost electronic orbitals. Compared with metal bonds, the covalent sharing of electrons is local (i.e., electron migration is limited to the nearest bonded atom), so polymers are almost always electrical insulators and poor thermal conductors. Compared with metal and ionic bonds, the covalent bonds between organic components are also relatively weak. Therefore, most polymers are easily degraded by exposure to UVC. High energy photons have enough energy to lift electrons to higher energy levels, thus breaking covalent bonds and degrading materials. Generally, polymers with carbon carbon double bonds are more vulnerable to UV degradation and chemical changes.

To sum up, how to prevent or reduce the degradation of materials by ultraviolet light?

Starting from the raw materials, the aluminum nitride material and gold plating process can effectively prevent the degradation of UV light and prolong the life of lamp beads. The ceramic base is filled with polymer to prevent UV from degrading the welding material at the bottom of the lamp bead through the support, improve the heat dissipation performance and effectively improve the stability of the product. In the light-emitting part, we choose quartz material with high transmittance. The essence of quartz glass is UV resistant, and it also has the dual effect of filtering impurity energy to improve UV transmittance and efficiency. The raw materials that are difficult to degrade by UV are used for production. After a long time of technical polishing, the UVC lamp beads that can be mass produced and do not affect the effect of anti-virus and sterilization have been fully realized.

Qingdao fluorescent Innovation Technology Co., Ltd. has a professional postdoctoral team, focusing on the research of ultraviolet sterilization application. After years of deep cultivation in the ultraviolet industry, the company has obtained a number of national invention and utility model patents. At present, a number of sterilization module products have been put into the market. For more details, please visit the company's website at www.qdyingguang.com Com contact the company for the official account of WeChat.

Keywords: 220nm, 230nm, 235nm, 240nm, 245nm, 250nm, 255nm, 260nm, 265nm, 270nm, 275nm, 280nm, 285nm, 290nm, 295nm, 300nm, 305nm, 310nm, 315nm, 320nm, 330nm, 340nm, 365nm, 395nm, 405nm, to39, uvworks, uvworks, UVC works, UVC EOS, UV LED, UVA led, UVB led, UV LED, deep UV LED, UV sterilization, UV disinfection, UV sterilization Ultraviolet disinfection scheme, sterilization module, water purifier sterilization, terminal sterilization faucet, static water sterilization component, flowing water sterilization component, ultraviolet sterilization water purifier, sterilization faucet, toothbrush sterilization, water cup sterilization, surface sterilization, water sterilization, air sterilization and phototherapy